|

| The right hand rail is insulated at the track circuit block boundary, the left is not. |

Your first option is to use the one rail or 1+1 system. Here you have one rail with insulated joints creating track circuit blocks and the other rail acting as a common ground without insulated joints. One downside is that only the insulated rail gets broken rail protection. There are probably other downsides as well as this method was only used on some of the oldest electrified transit systems such as the NYC Subway. Another option is to have a 4th rail system like the London Underground where traction return current uses a dedicated 4th rail instead of the running rails. The better option is to use a device called an impedance bond to have both isolated track circuit blocks and a traction return path via the rails.

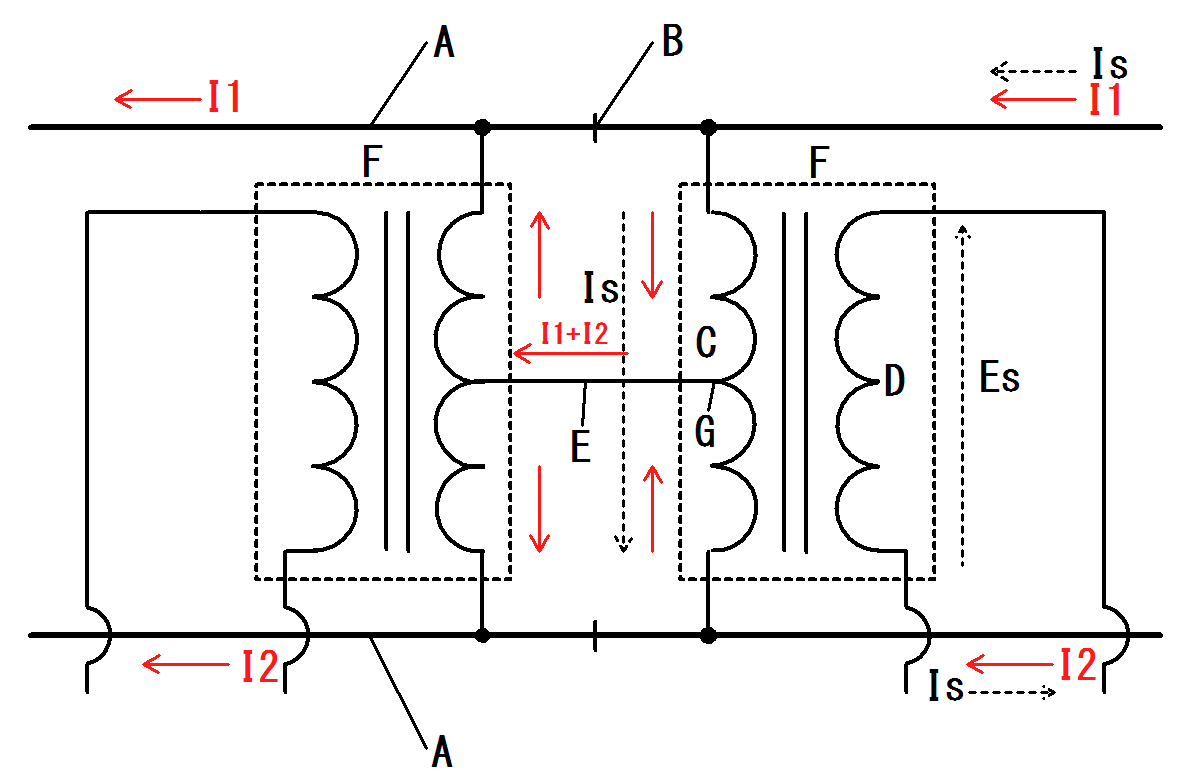

Here we see a Union Switch and Signal model impedance bond, patented in 1922. I am not sure if there were any earlier models of bond or if this was used on the 1915-1918 PRR and New Haven 25hz electrification projects before the patent was granted, but it would have been available for the major waves of electrification that took place in the 1920's and 30's. An impedance bond is a type of isolation transformer where traction return current can pass with low impedance (impedance is the AC version of resistance), while track circuit current faces high impedance and thus follows the path of least resistance through the track circuit logic. The necessary trick to making this work is to have track circuit current at a different frequency than the traction return current. For example DC traction current with an AC track circuit or one frequency of AC return current with another frequency of AC track circuit.

In the above diagram from a Japanese Wikipedia page we can see a slightly more elaborate setup for an impedance bond. The two coils connected at the center tap are what constitute the impedance bond. The secondary windings capture the AC track circuit current via the magic of induction and feed the signal logic. More typically the bond omits this secondary winding and the signal logic is fed directly from the rails. Remember this is a super high level summary so for more detailed technical information please consult Google or your reference library.

Here we see two of the 1922 patent US&S bonds and their modern Siemens replacements for use on Amtrak's NEC. Amtrak, like the PRR before it, uses 25hz traction power and 91.66hz coded AC track circuits. Normally the coded track circuits would operate at 100hz, but as a multiple of 25, return current harmonics could be detected as track circuit current, which is bad. 91.66hz is close enough to 100hz to be cross compatible with 100hz electronics.

The spec plate on the new bonds show the Amp rating for traction return current and the impedance values for 100hz current (400 ohms) and 60hz current (2.4 ohms). While 25hz isn't listed I am assuming that the value would be in an acceptable range. A DC traction system sees much higher amp loads than an AC system and therefore the bonds must be much larger with thicker windings to handle it. Systems with both AC and DC, like Penn Station, would use DC rated bonds.

Of course the story doesn't stop there. In the late 1960's the rail signaling industry introduced the concept of jointless track circuits for use in transit applications. These make use of AC frequencies in the "audio" range of 1-5 kHz. These higher frequencies attenuate after a much shorter distance and using a mix of frequencies one can have a given track circuit receiver able to hear the signal from a single specific transmitter. Still there is the issue of the pesky traction return current that needs to move between the rails, to ground and NOT into the signaling logic. The solution was the Wee-Zee bond (trademark of GRS) that creates this path to ground while preventing the track circuit signal passing between the two rails.

In this close up of a US&S "Minibond" on the Chicago El, we can see the the listed transmit-receive frequency pairs, the cab signal code frequency and the DC power rating (3000amps at 0.00003 ohm).

Now if you like Technology Connections, here's an interesting one for you that revolves around the necessity of impedance bonds. Europe is currently under the thrall of axle counters for train detection as opposed to track circuits. Why would the normally safety conscious Europe in interested in a train detection system that doesn't positively detect the presence of a train (or flood or broken rail)? Because the Central European 16.66Hz electrification club, which includes Germany, Austria, Switzerland and a few others, electrified their rail systems were those systems were still operated using non-track circuited manual block signaling. When upgrading to automatic block signaling, installing track circuits would require installation of impedance bonds and related electronics. Therefore an alternative, axle counters, was sought out and adopted.

Likewise, the NYC Subway is moving to Communications Based Train Control instead of the audio frequency track circuits as their use of the one rail system would require the installation of who knows how many Wee-Zee bonds. Just goes to show how technical decisions can be highly path dependent. Keep that in mind the next time you have trouble figuring our the logic behind that might not make complete sense.

What is the yellow gadget mounted practically in front of the upper head of the NYC subway signal photo above?

ReplyDeleteIt's a key by button. To pass a signal at stop the operator pulls up and presses the button. It will drive down the trip arm.

Delete"15.66Hz" - you mean "16.66Hz"; but it was actually changed to 16.7Hz in the mid 90s. See e.g. this WP section for the reason behind this.

ReplyDelete91.66hz is only used in areas where DC traction power is also used (around NYP) the presence of the DC propulsion and equipment made the not-usually-plausible second harmonic of 25hz (100hz) actually happen.

ReplyDelete